Polycarbonate vs. Acrylic for Transparent Parts: Making the Right Choice with Gemini Plastics Inc.

- Nov 12, 2025

- 2 min read

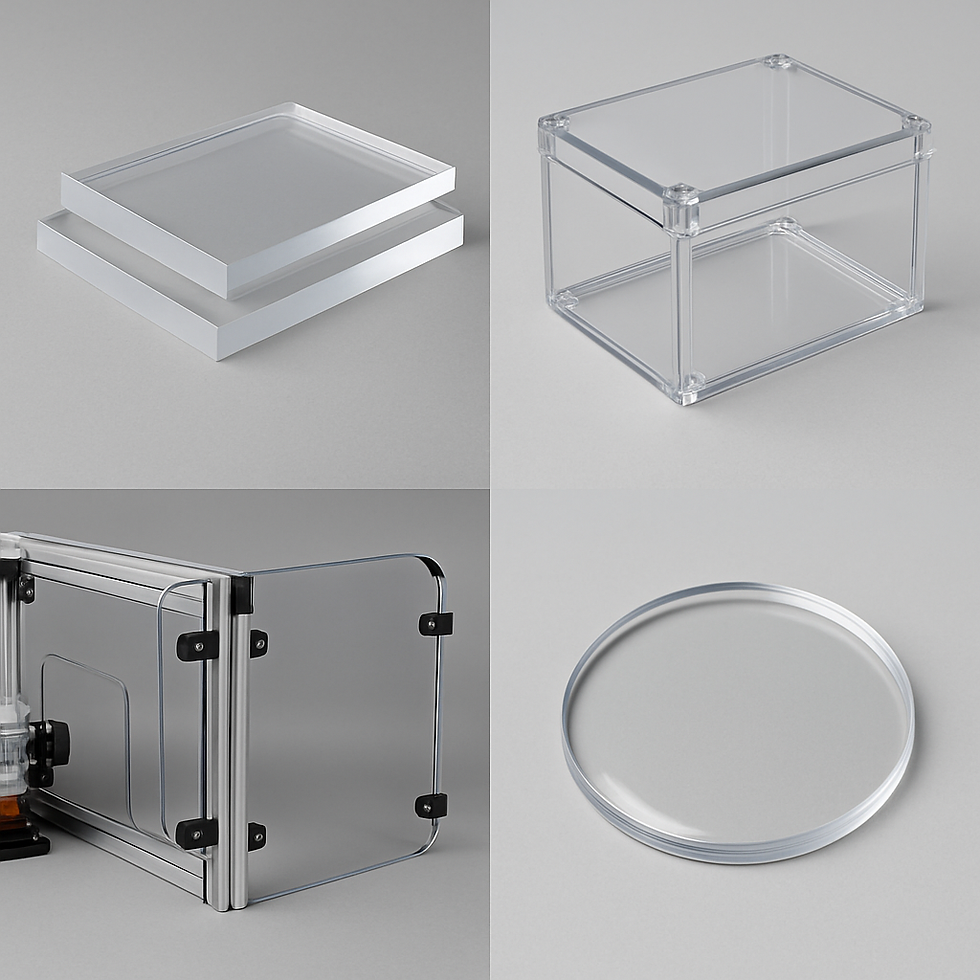

When designing transparent components, the choice of material is pivotal. Polycarbonate and acrylic are both widely used alternatives to glass—but they differ in key areas like durability, clarity, cost, and performance. At Gemini Plastics Inc., we excel in providing tailored solutions with precision-engineered plastics, whether your project leans toward aesthetic appeal or rugged durability.

1. Optical Clarity & Aesthetics

Acrylic (PMMA) stands out for stunning visual clarity and brilliance. Its glass-like transparency makes it ideal for projects where appearance is paramount—think display cases, signage, and architectural features.

Polycarbonate (PC) also offers excellent clarity, though slightly less transparent (around 88–90%). Even so, it works superbly for components like machine guards or architectural glazing where both visibility and resilience are needed.

2. Impact Resistance & Toughness

Polycarbonate is the undisputed champion when it comes to strength—it’s nearly indestructible. For instance, it can be up to 200–250 times more impact-resistant than glass, making it ideal for high-stress applications such as safety equipment, protective barriers, or headlight lenses.

Acrylic, while much lighter and more impact-resistant than glass, is more brittle than PC and can crack or shatter under significant force.

3. Machinability & Fabrication

Acrylic is a favorite for its easier machining: it cuts clean, bonds well, and can be polished to a flawless finish.

Polycarbonate requires more care—it scratches more easily and often needs special tools or coatings for protection—but it's significantly more flexible and can be bent or thermoformed even at room temperature.

4. Weather Resistance & UV Stability

Acrylic typically withstands long-term outdoor exposure with minimal UV degradation, retaining its appearance over time.

Polycarbonate, while durable, is more UV-sensitive and prone to yellowing; UV-stabilized grades or protective coatings are often necessary for exterior applications.

5. Cost Considerations

Acrylic generally costs less—on average up to 35% cheaper than polycarbonate—offering valuable savings for visually focused or large-volume projects.

Polycarbonate, while more expensive, delivers a higher return on investment when longevity and resilience in demanding environments are top priorities.

6. Application Highlights

Application Need | Recommended Material | Why It Fits with Gemini Plastics’s Capabilities |

Display cases, signage, aesthetic parts | Acrylic (PMMA) | High clarity, polishability, and cost-efficiency. |

Protective guards, safety shields | Polycarbonate (PC) | Exceptional toughness and impact resistance. |

Outdoor glazing, skylights | Acrylic | Superior weathering and UV resistance. |

Enclosures needing flexibility and durability | UV-stabilized Polycarbonate | Resilient, flexible, and strong—coated for outdoor use. |

Complex parts with cosmetic finish | Either, depending | Gemini Plastics offers precision molding and finishing to suit aesthetic needs. |

Why Choose Gemini Plastics Inc.?

With a robust material selection guide that includes many industrial-grade plastics, including PETG and more, Gemini Plastics Inc. delivers precision-engineered parts tailored to your project's needs. Whether you require the optical beauty of acrylic or the rugged durability of polycarbonate, Gemini’s team ensures the right balance of performance, clarity, and cost—backed by expert manufacturing and a focus on cosmetic quality.

Choosing between acrylic and polycarbonate depends on your project’s priorities—whether that’s optical clarity, durability, weather resistance, or budget. At Gemini Plastics Inc., we’ll help you navigate these trade-offs and deliver parts that meet your specifications. Let’s collaborate to bring your transparent component visions to life with the right plastic.

Comments