Our Plastic Injection Molding services provide an unparalleled opportunity for projects that demand low tooling costs for short to moderate production runs. Typical runs range from 1,000 to 250,000.

Capable of injection molding large, complex parts, we design our own tooling, ensuring a quick turnaround on all phases of product realization. Our customers are guided from the earliest prototype stages through full production by our experienced engineers and estimators.

What is the Molding Process?

At Gemini Plastics, Inc., you will find a team of seasoned professionals that will provide you with plastic injection molding products and services that can meet the most stringent requirements for quality.

With the ability to fabricate parts from a large range of materials, including ABS, Delrin®, and moly filled nylon, we are able to hold to very tight, .002" tolerances for your high-precision plastic part needs. We provide RTIs (rapid tooling inserts), which permit faster turnaround of prototypes and short production run projects.

Our modern, automated facility enables us to run lights-out operations, increasing production speed to meet the most demanding schedules. We have expertise serving many industries, including recreational vehicles and other transportation industries, as well as electronic, snow removal, and general industrial. Additional services we provide include sub-assembly operations and engineering support. Contact Gemini Plastics today to learn how our plastic injection molding services can improve your application.

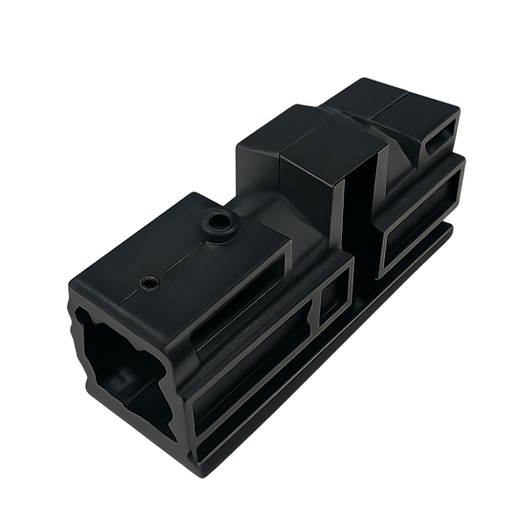

Injection Molded Finger for Paper Processing Equipment

Paper Converting Industry

This precision-molded component—commonly referred to as a “finger”—is used in high-speed paper converting equipment to guide, stabilize, or separate sheets during processing. Designed to perform reliably in continuous motion environments, it withstands repeated impact and contact with moving substrates without deformation or wear.

Molded from high-strength polycarbonate, this part offers excellent toughness, dimensional stability, and impact resistance—making it a durable solution for high-speed converting applications. Its ribbed and contoured geometry enhances structural rigidity while minimizing weight, optimizing both strength and production efficiency.

We produce this component using production-grade tooling to ensure repeatability and tight process control.

Our process includes regular in-process inspection checks to maintain consistency across runs. This component is one of many parts we supply to OEMs in the converting and packaging industries, supporting high uptime and reliable equipment performance.