Gemini houses four CNC Routing machines which concurrently handle numerous projects from diverse industries, including paper converting, snow removal, transportation, infrastructure and agricultural industries.

From single-piece prototypes to thousands of parts, we accommodate material up to 3” thick, 60” wide, and 26' long, maintaining tight tolerances of .015” throughout production.

CNC Machining Design Guidelines

At Gemini Plastics, we offer precision CNC plastic routing and shaping to fabricate custom components for customers across a spectrum of industries and applications. Our state-of-the-art equipment features 3 and 5 axes, CNC control, CAM programming, dual spindles, and automatic tool changers. Our experts create parts to exacting specifications from materials including acetal, nylon, PTFE, polyethylene, and polycarbonate, in sizes up to 324" (8,299.6mm) in length and up to 72" (1828.8mm) in width, maintaining tight tolerances of ± 0.001” throughout production. We also offer the design and manufacturing of vacuum-formed tooling, and ancillary bonding assembly services.

Typical turnaround times for custom components are 2 to 3 weeks, with rush options. Also available are special packaging and freight handling options. We handle the volume from prototype to production. All of our products and processes uphold the highest standards of ANSI, ASTM, ASME, and Mil-Spec. We are dedicated to bringing customers the best in plastic part production and stand by our products for their lifecycle.

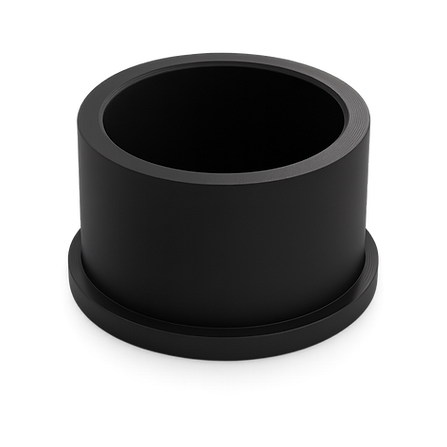

CNC Machined Spacer

Lithium Battery Industry

This HDPE spacer is precision-machined for integration in a lithium battery application, where it provides consistent separation and insulation between key internal components. Its role is essential to maintaining the structural and electrical integrity of the system.

HDPE is selected for its excellent dielectric strength, chemical resistance, and dimensional stability—qualities that make it particularly well-suited for electrically sensitive assemblies such as battery enclosures.

We machine this component using modern CNC equipment to meet strict dimensional requirements and ensure repeatable performance. Each production run is inspected to confirm compliance with specifications, with periodic in-process checks conducted throughout machining to ensure consistent quality.

This part reflects our commitment to delivering reliable, high-performance plastic components for OEM applications—on time and with dependable consistency.